PRECISION DOOR OF MISSION VIEJO

PRECISION DOOR OF MISSION VIEJO

Precision Door Parts & Accessories

Precision Door Parts & Accessories

At Precision Door of Mission Viejo, we pride ourselves in being able to provide our customers with the very best our industry has to offer. When it comes to our parts, we have done our research to figure out exactly what our customers need. We know this can be confusing if you don’t work with garage doors every day, so we’ve put together this comparison to clearly explain the biggest differences that matter to you.

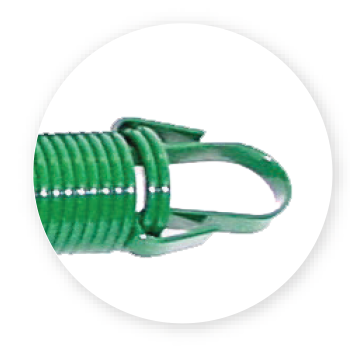

EXTENSION SPRINGS

We use a green powder coated extension spring with a heavy-duty clip end to ensure top-notch strength and reliability.

Other companies will use a contractor grade spring that uses a loop end, which will weaken, break or fail more quickly over time.

TORSION SPRINGS

Precision uses a green powder coated spring to protect from rust and damage. They also have a higher life cycle, which makes them last up to 5 times longer.

Others will use a standard, non-coated torsion spring that will eventually rust and wear out over time.

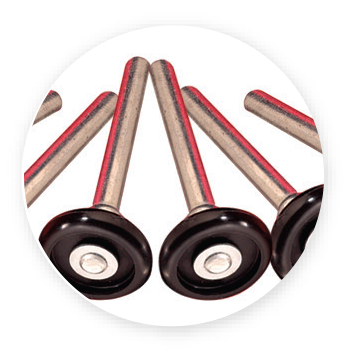

ROLLERS

Precision uses dust-capped rollers that have a sealed 13-ball bearing, making them much quieter. They last far longer than other rollers and never need to be lubed.

Other companies will use noisy rollers without a bearing, causing them to shake and wear down more quickly or even break prematurely.

CABLES

Precision uses more flexible and quieter stainless steel aircraft grade cables with 19 wires per strand, which last longer than standard cables.

Other companies use standard cables that only utilize 7 wires per strand, and are less flexible and more noisy.

PULLEYS

Precision uses a cast iron pulley for strength and durability. The no-seam design ensures cables roll through pulleys smoothly.

Other companies use a light-duty sheave pulley. These will eventually separate and cause the door to strain severely.

CENTER BEARING

Precision uses a center bearing that utilizes bearings to help assist the entire torsion system to operate smoothly.

Other companies will use a center bearing that is made of plastic, with a plastic bushing, and only provides center support.

HINGES

Our hinges use a thicker steel, which means no cracking or breaking.

Other companies use lightweight steel causing them to be flimsy and break or snap more easily.

CENTER BEARING BRACKET

Precision uses a center bearing bracket that is made out of thicker steel and comes assembled with a high-quality bearing.

Other center bearing brackets are made out of lower grade steel, causing them to flex and bend during use.

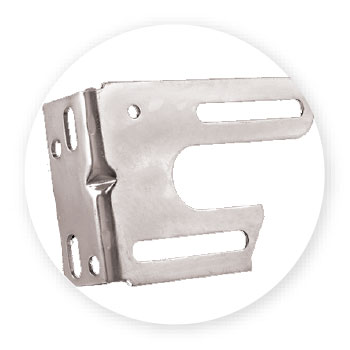

END BEARING BRACKETS

Our end bearing plates bolt directly to the track and wall, giving them four connection points in order to prevent binding of the torsion system.

Others use end bearing brackets made of un-reinforced steel, and only have two points in which they are secured.

NEED A PART? CALL US TODAY!

PRECISION DOOR OF MISSION VIEJO

Precision Door Parts & Accessories

At Precision Door of Mission Viejo, we pride ourselves in being able to provide our customers with the very best our industry has to offer. When it comes to our parts, we have done our research to figure out exactly what our customers need. We know this can be confusing if you don’t work with garage doors every day, so we’ve put together this comparison to clearly explain the biggest differences that matter to you.

VS

EXTENSION SPRINGS

We use a green powder coated extension spring with a heavy-duty clip end to ensure top-notch strength and reliability.

Other companies will use a contractor grade spring that uses a loop end, which will weaken, break or fail more quickly over time.

TORSION SPRINGS

Precision uses a green powder coated spring to protect from rust and damage. They also have a higher life cycle, which makes them last up to 5 times longer.

Others will use a standard, non-coated torsion spring that will eventually rust and wear out over time.

ROLLERS

Precision uses dust-capped rollers that have a sealed 13-ball bearing, making them much quieter. They last far longer than other rollers and never need to be lubed.

Other companies will use noisy rollers without a bearing, causing them to shake and wear down more quickly or even break prematurely.

CABLES

Precision uses more flexible and quieter stainless steel aircraft grade cables with 19 wires per strand, which last longer than standard cables.

Other companies use standard cables that only utilize 7 wires per strand, and are less flexible and more noisy.

PULLEYS

Precision uses a cast iron pulley for strength and durability. The no-seam design ensures cables roll through pulleys smoothly.

Other companies use a light-duty sheave pulley. These will eventually separate and cause the door to strain severely.

CENTER BEARING

Precision uses a center bearing that utilizes bearings to help assist the entire torsion system to operate smoothly.

Other companies will use a center bearing that is made of plastic, with a plastic bushing, and only provides center support.

HINGES

Our hinges use a thicker steel, which means no cracking or breaking.

Other companies use lightweight steel causing them to be flimsy and break or snap more easily.

CENTER BEARING BRACKET

Precision uses a center bearing bracket that is made out of thicker steel and comes assembled with a high-quality bearing.

Other center bearing brackets are made out of lower grade steel, causing them to flex and bend during use.

END BEARING BRACKETS

Our end bearing plates bolt directly to the track and wall, giving them four connection points in order to prevent binding of the torsion system.

Others use end bearing brackets made of un-reinforced steel, and only have two points in which they are secured.

NEED A PART? CALL US TODAY!

PRECISION DOOR OF MISSION VIEJO

Google Reviews

Google Reviews

Google Average Review is 4.9/5 Stars

REQUEST A CALLBACK

Need Repair Service or New Door?

Fill out the form and one of our associates will call you and set up an appointment.